Whether you’re a contractor, engineer, or architect managing a construction project in Bangladesh, achieving a smooth finish on your internal and external walls isn’t just about looks—it’s about structural integrity, durability, and cost-efficiency.

From cement plaster ratio to volume of mortar, everything must align with precise specifications. This blog dives deep into calculating the right quantity of cement and sand for plastering, helping you avoid common mistakes and ensuring a successful construction project—with a special spotlight on why AKIJ Cement is the trusted choice for quality.

Understanding Cement Plaster and Its Role in Construction

Plastering creates a protective layer on your building surface, helping prevent damage from moisture, weather conditions, and accidental wastage. A proper plaster layer not only enhances the aesthetics of walls but ensures long-term durability.

There are several types of plaster (e.g., clay plaster, lime plaster, cement plaster), but for high-performance structures, cement plastering—especially using Portland Slag Cement or Ordinary Portland Cement—is the essential step.

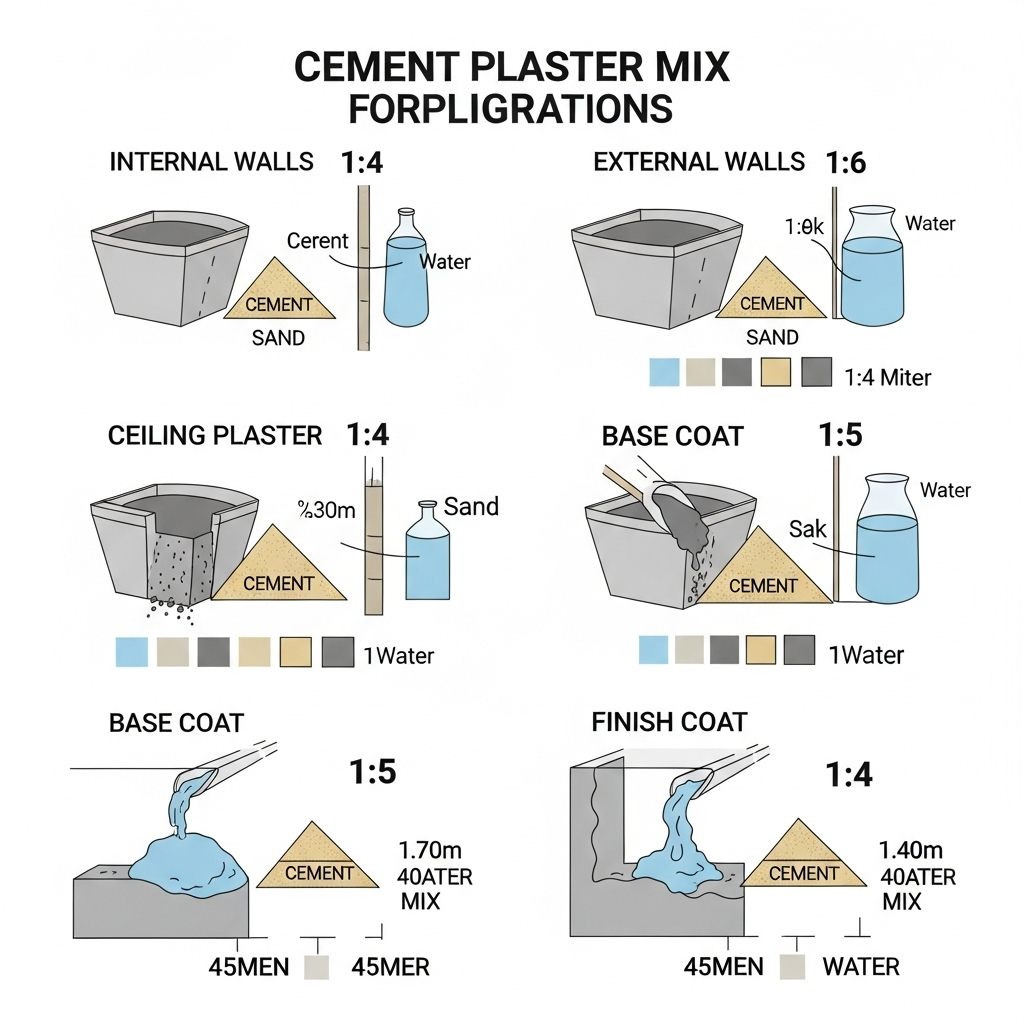

Common Cement Plaster Mix Ratios

Selecting the right cement plaster mix ratio depends on the type of surface, weather exposure, and project requirements.

Common Ratio for Plastering

| Surface | Plaster Thickness | Ratio of Cement : Sand | Application |

| Internal walls | 12 mm | 1:4 | Smooth surface, stronger bond |

| External walls | 15–20 mm | 1:6 | Weather resistance |

| Ceiling plaster | 12 mm | 1:4 | Smoother finish |

| Base coat / Primary coat | 10–15 mm | 1:5 | First application layer |

| Finish coat / Secondary coat | 6–8 mm | 1:4 | Final touch |

These common plastering mortar thicknesses help create a durable surface that’s ready for premium quality painting or finishes.

How to Calculate Cement and Sand for Plastering

Whether you’re working in square meters, feet, or cubic meter measurements, follow this approach to calculate the accurate cement quantity and volume of sand:

Step 1: Calculate Wet Volume

Let’s assume 1 sqm plastering with 12 mm plastering thickness.

Wet Volume = Area × Thickness

= 1 sqm × 0.012 m = 0.012 m³

Step 2: Convert to Dry Volume

Dry volume = Wet volume × 1.33 (to allow for bulkage of sand and wastage)

= 0.012 × 1.33 = 0.01596 m³

Step 3: Apply Mix Ratio (1:4)

Total parts = 1 (cement) + 4 (sand) = 5

- Volume of cement mortar = (1/5) × 0.01596 = 0.00319 m³

- Volume of Sand = (4/5) × 0.01596 = 0.01277 m³

Step 4: Convert Volume to Weight

- Density of Cement = 1440 kg/m³ → Cement = 0.00319 × 1440 = 4.6 kg

- That’s ~0.092 of a 50 kg cement bag

So, for 1 square meter plastering, you’ll need:

- ~4.6 kg of cement

- ~0.45 cubic feet of sand

For 100 sq ft (~9.29 m²):

- Cement = ~1 bag (50 kg)

- Sand = ~3.2 cubic feet

Scale quantities proportionally for larger areas like 100 m², 1000 sq ft, or entire floor/wall plastering.

Why Use AKIJ Cement for Plastering?

Contractors often face the challenge of project delays, excessive moisture, or durability failures due to inferior cement in plaster. Here’s where AKIJ Cement excels.

1. Superior Mix Compatibility

Its slag-based formula ensures a smoother finish and better bond with sand for plastering. Ideal for:

- Internal plastering

- External rough coats

- Ceiling with cement plaster

2. Precise Dry Density Volume

Thanks to Vertical Roller Mill (VRM) technology, AKIJ ensures the optimum cement mortar ratio—resulting in a more consistent volume of cement mortar and accurate calculation during batching.

3. Stronger Chemical Composition

AKIJ’s CEM-II/B-M contains higher CaO, generating more CSH Gel, which:

- Resists chemical reactions

- Reduces cracks due to thermal stress

- Protects against estuarine water and brackish water

4. Trusted by Engineers

- Complies with BDS EN 197-1:2010

- Tested by BUET, aligned with ASTM standards

- Performs under all outdoor conditions

5. Uninterrupted Supply & Logistics

- Own fleet of cement bags, trucks, and mother vessels

- Reduced chances of supply chain disruption

Cement Types & Their Best Use Cases

| Type of Cement Used | Best for | Benefits |

| Ordinary Portland Cement (OPC) | Mega structures, bridges | Higher strength |

| Portland Pozzolana Cement (PPC) | Damp areas | Long-term durability |

| Portland Slag Cement (PSC) | General & aesthetic finish | Smooth surface, sulfate resistance |

| White Cement | Decorative plaster | Aesthetic finish, paint base |

| Grey Cement (Blended) | Common types of interior work | Standard strength |

Field Tips for Proper Plastering

- Use clean water—avoid polluted or brackish water.

- Check bulkage of sand—wet sand expands.

- Ensure the silt content is <8% for better bond.

- Don’t exceed 12–15 mm coat of plaster in one layer.

- Cure the plastered surface for at least 7 days to prevent cracks.

FAQs

- What’s the standard volume of cement used per square meter of plaster?

A: Roughly 4.6 kg of cement per 1 sqm (for 12 mm thickness, 1:4 mix ratio).

- How many cement bags required for 1000 sq ft plastering?

A: Approx. 10–11 bags of cement depending on the plastering thickness and mix ratio.

- What’s the ideal sand ratio for plastering internal walls?

A: For internal walls, use a 1:4 cement to sand ratio to achieve a durable finish.

Conclusion: Build Smart with the Right Mix

Choosing the right cement for plastering ensures a durable surface, beautiful walls, and a hassle-free construction process. With AKIJ Cement, you’re not just getting bags of cement—you’re investing in a blend of cement technology, consistency, and performance that delivers results.

📞 Need bulk supply for your project? Contact us at 08000 555 777

🌐 Learn more at www.akijcement.com